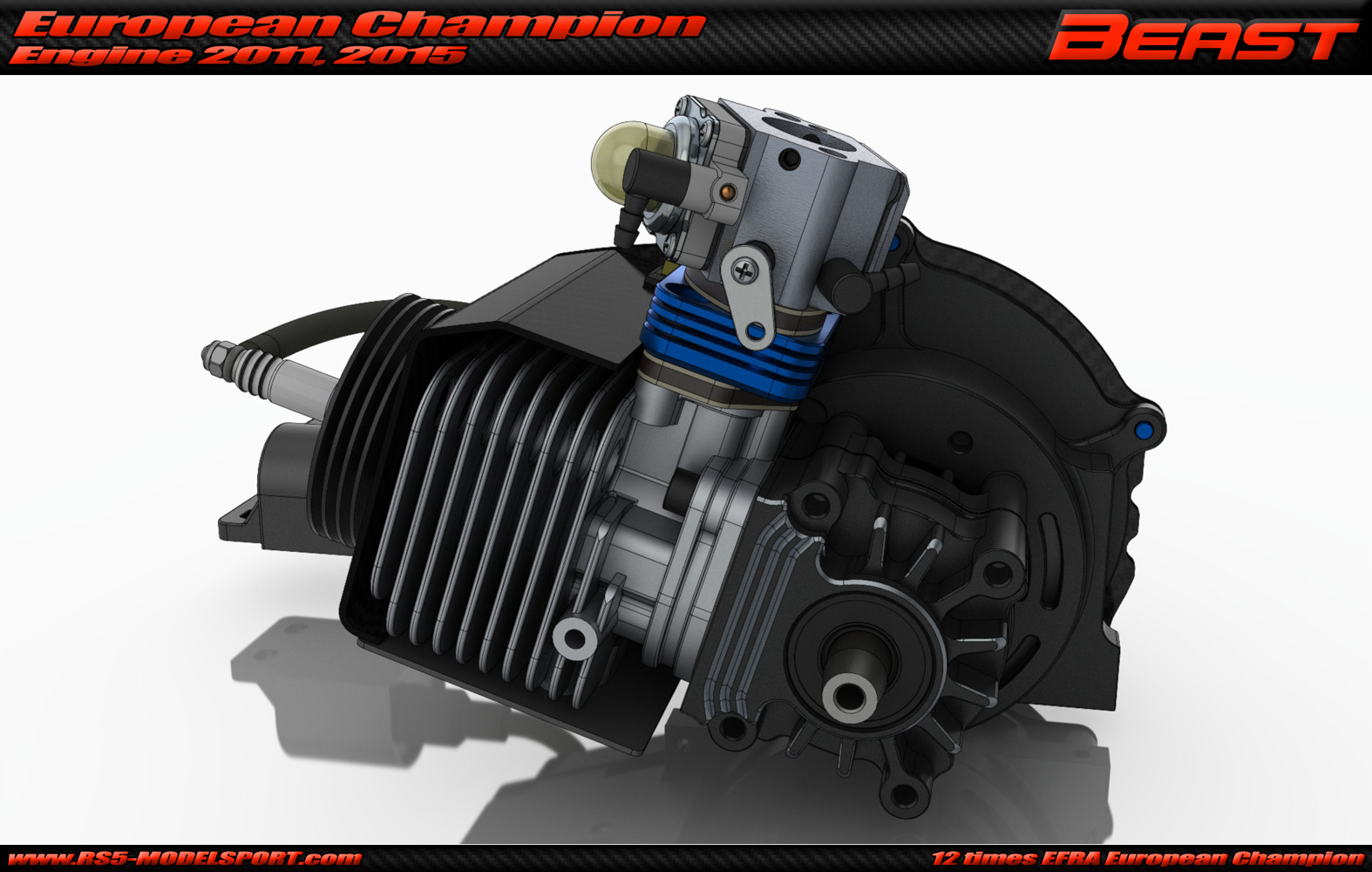

RS5 - Beast Engine Features

Back at 2011 we decided to lounch a car and engine project - called “TX” - where the engine has an CNC

machined crankcase and it is structural part of the car. The main idea behind this project was to make the engine as low positioned as possible to reduce the center of gravity of the car and to

make the car 100% symmetrical.

The first test showed huge potential of this concept, by winning the 2011 European Championship by Martin Bayer. After the victory we decided to work more and more on this concept before we put

it on the market, to be sure that everything was perfect. We decided not to use this concept in 2012 and 2013 at Big Races, where we run the T series cars (T12 and T13) instead of the Tx series

car. But our development continued in the background and specially in the second half of 2014 and during 2015 we redesigned several time the engine and the chassis until it got its final shape.

The 2015 European Championship was the last big test of the completely redesigned Beast engine and the Tx chassis, where it showed its potential against the best drivers, cars and engines all

over the world in an sweltering heat (35+ degrees). The Tx chassis and the Beast engine proved their power during this event by making track record and winning the 2015 European Championship by

Ales Bayer. The Beast engine was one of a few engine in the Austrian summer heat that had no problem with overheating and had no problem with fuel economy.

This kit is a cost efficient option for you to have an spare engine. It includes a ready to run Beast engine (22800) without the following components: Ignition Coil, Spark plug, Cylinder heatsink, Engine covers.

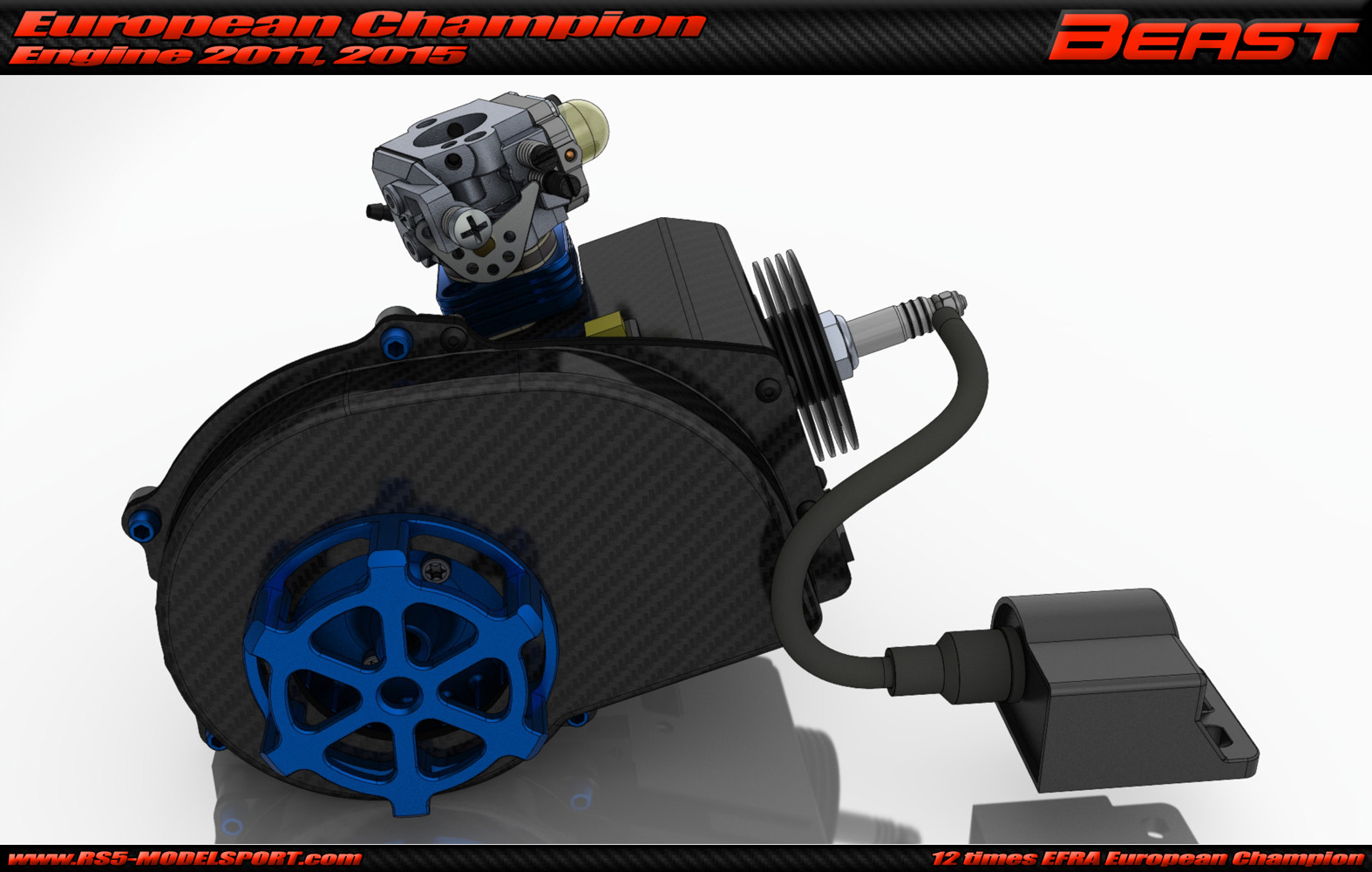

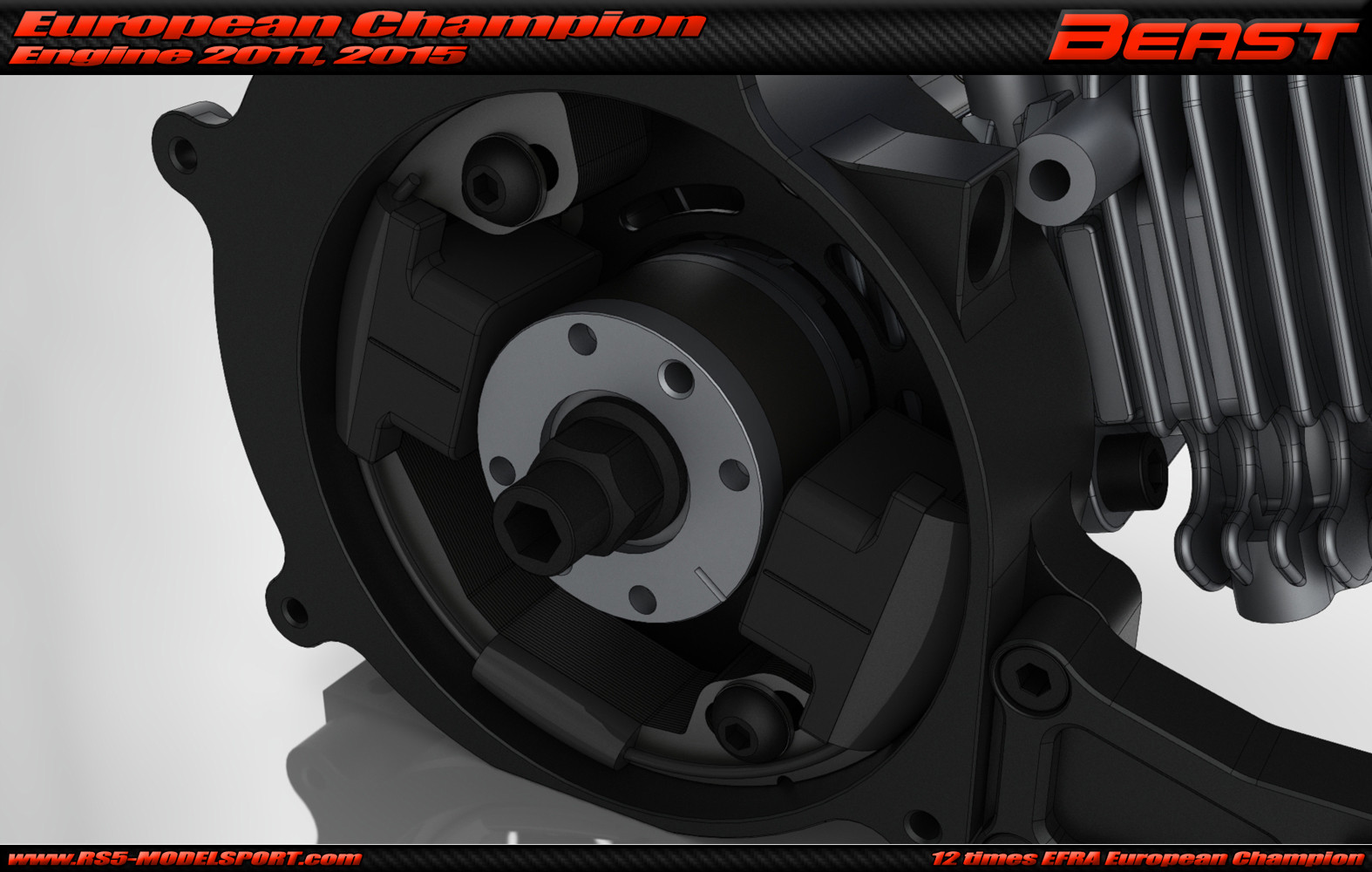

Ignition Housing

The ignition system's rotor sits behind the ventilator, not like on stock Zenoah engines. With this layout the cylinder cooling is better, because there is nothing (ignition) in the airflow, so the engine cooling becomes more efficient. The ignition housing is made of 7075-T6 aluminum and CNC machined, which makes the right side of the car as stiff as the left side, where the engine fixing components are. With this solution engine becomes structural part of the car and acts as a load carrying element and not just as power source.

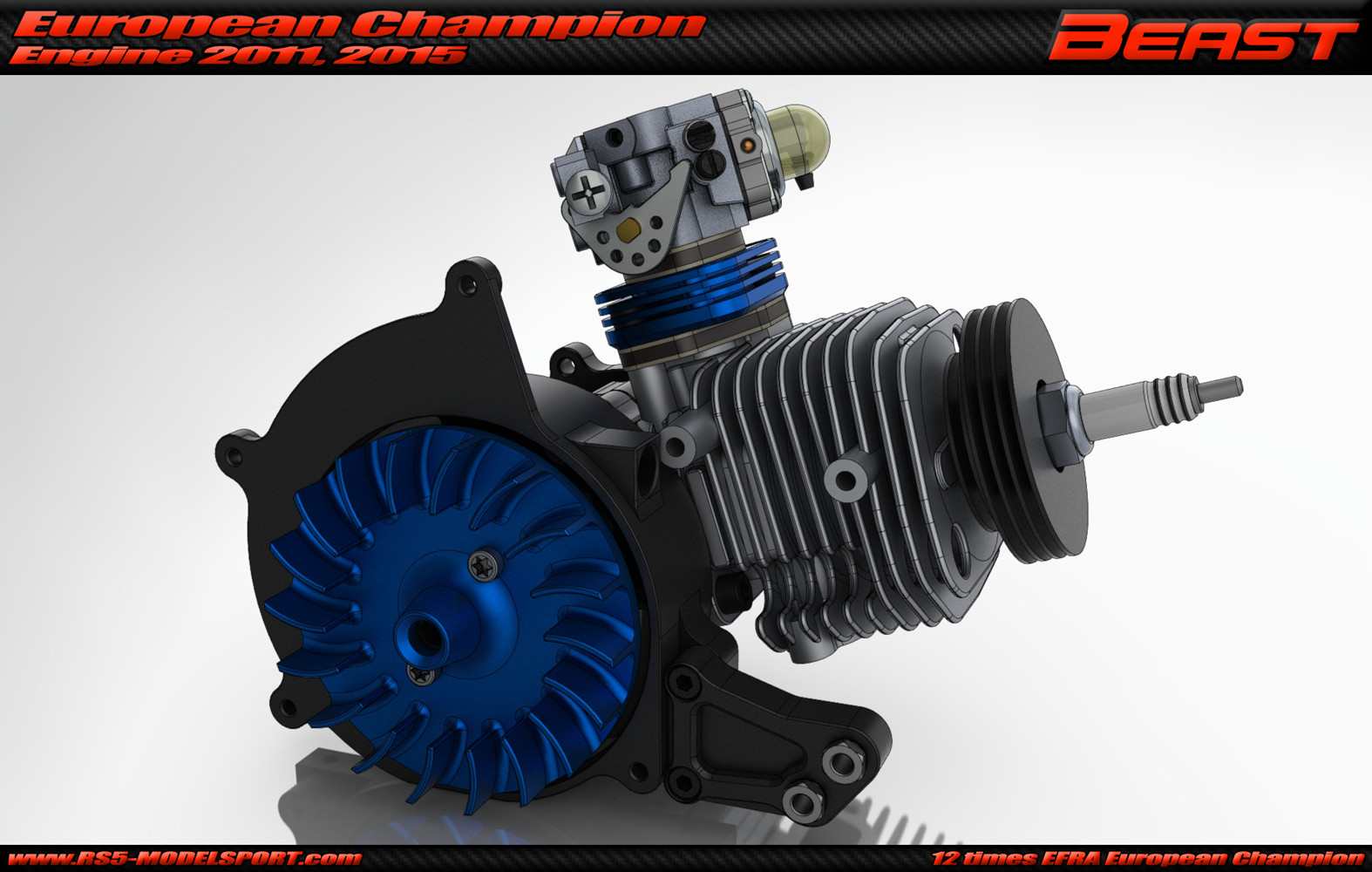

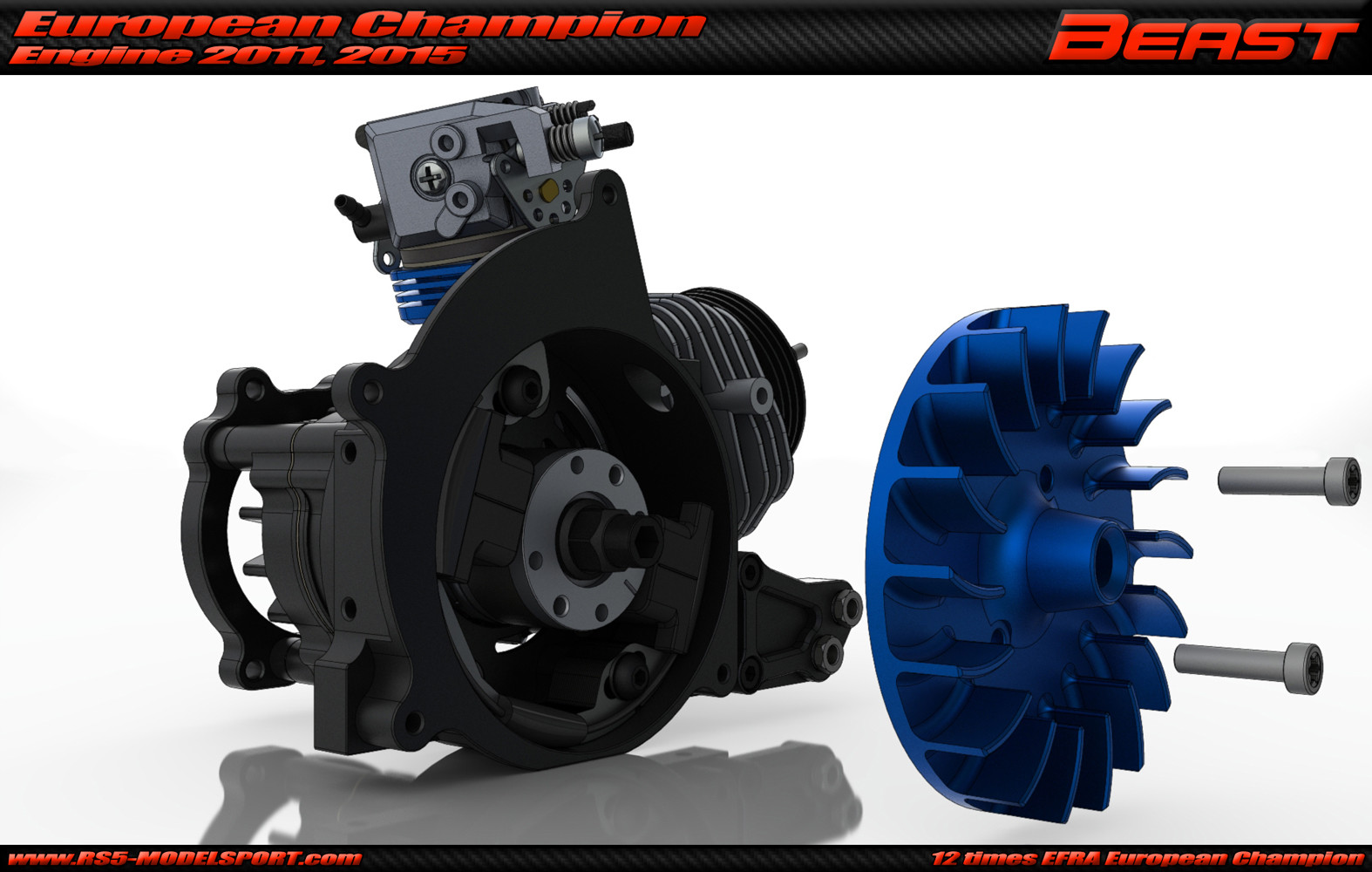

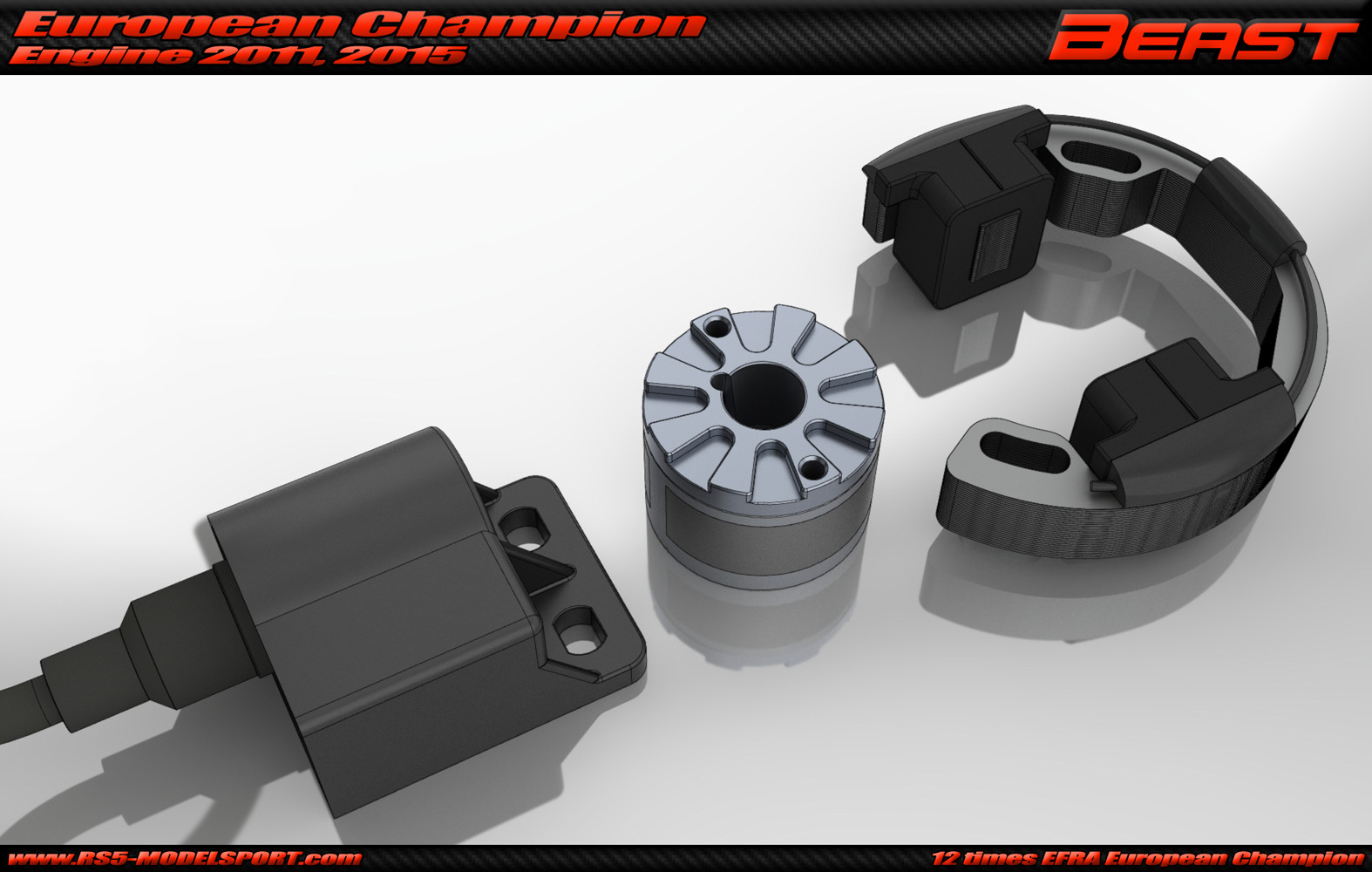

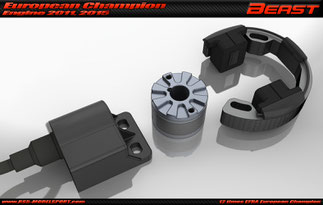

Ignition System

The Beast engine has Selettra ignition system. This type of ignition has 3 main components. The first component is the external ignition coil, which is detached from the engine cover. The placement of this part is free, we usually fix it to the side of the car, next to the battery. The second component is the ignition stator, which is bolted to the ignition housing. The stator has oval holes, so the advance-ignition can be adjusted between zero and 30 degrees. The third part is the ignition rotor, which is bolted to the standard Zenoah crankshaft, with a special adapter and a nut. This special nut has hexagon inside to let start the engine with an external electro-starter. This special adapter aligns the rotor to the optimal ignition timing range with his keylock slot.

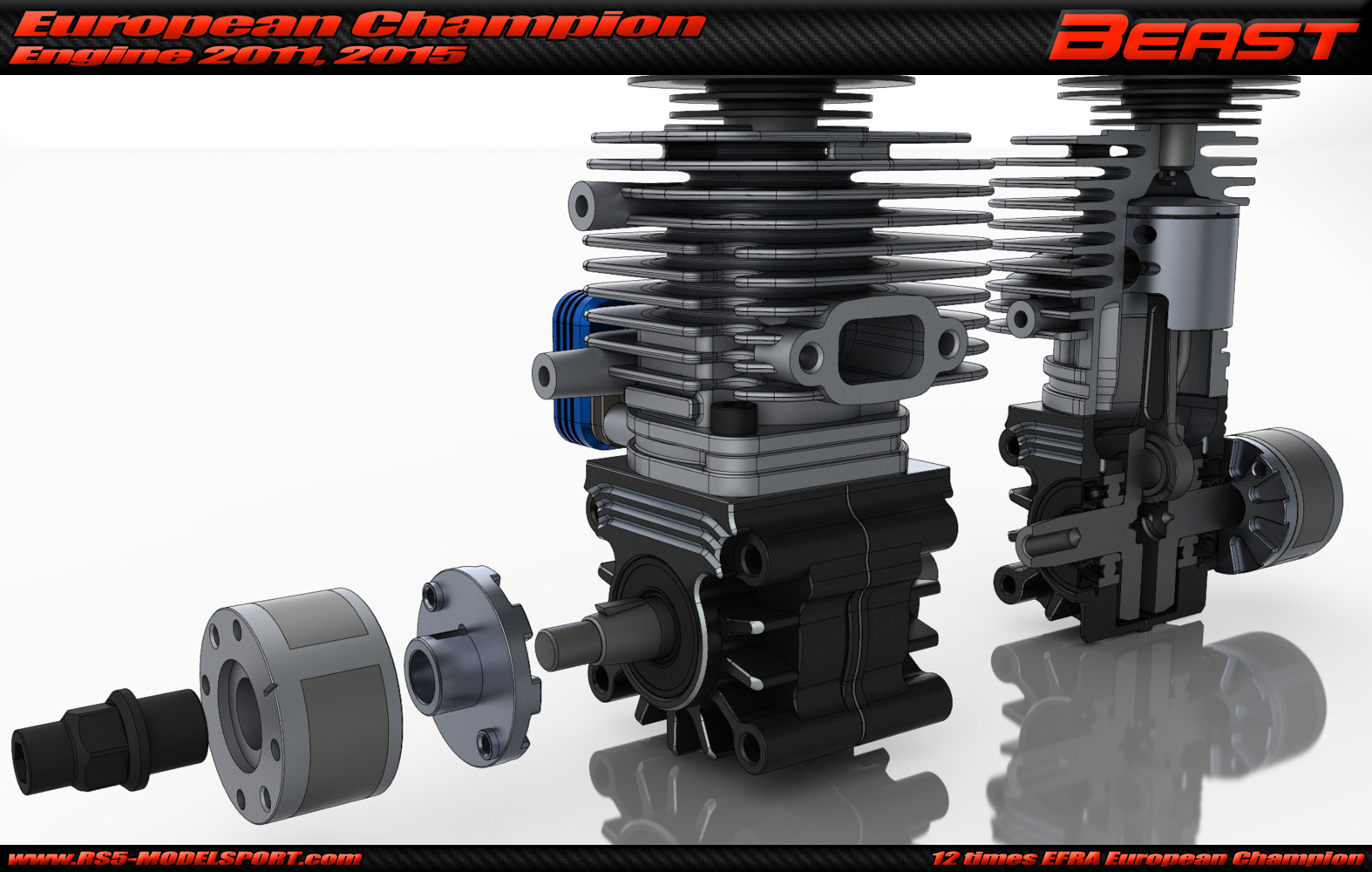

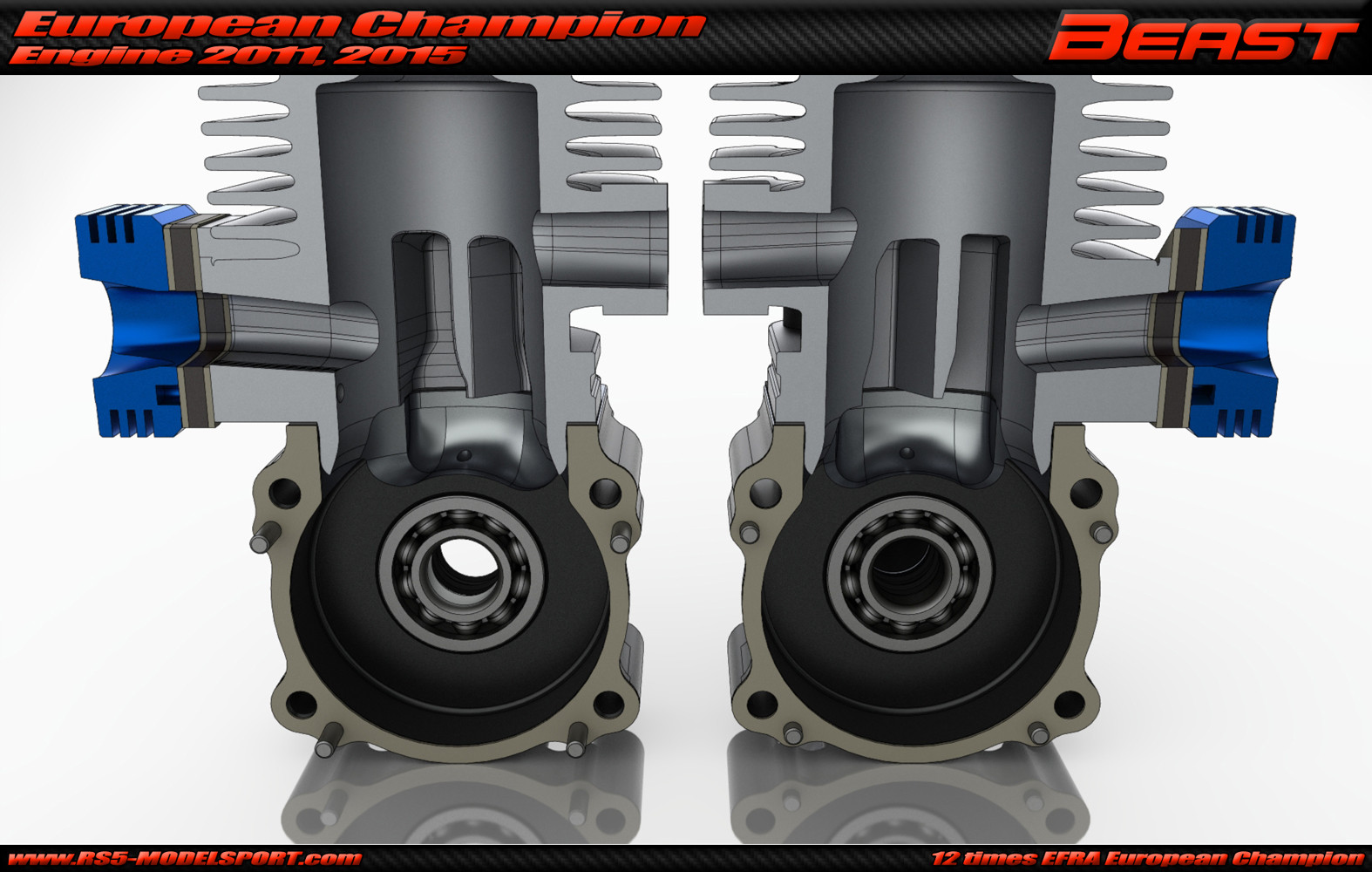

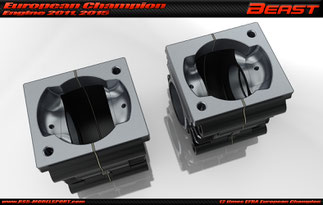

Crankcase

Our two piece compact Crankcase made of a special alloy that has very high heat dissipation and both are 100% CNC machined. Before they got the final shape, a lot of prototype was made and tested, until we reach the current channel and port design. Extra stiffeners and cooling ribs were added to the crankcase to support the main ball-bearing and to support heat dissipation. The left and right side of the crankcase are machined together, to keep as small as possible production tolerances. During machining the left and right side crankcases are marked together, to assure they stay together during engine assembly.

Flow Optimization

The channels of the crankcase and the insulator are 3D CNC machined, which perfectly match with the ports of the Zenoah cylinder. The shape of the two side channels of the crankcase are very important, therefore they are optimized, because they define the way and direction of the gas-flow. Our alloy insulator has heatsinks to increase the heat dissipation and to cool down inspired air. The shape of its inside channel is very important, so they are optimized to let the air in the cylinder in the best possible direction.

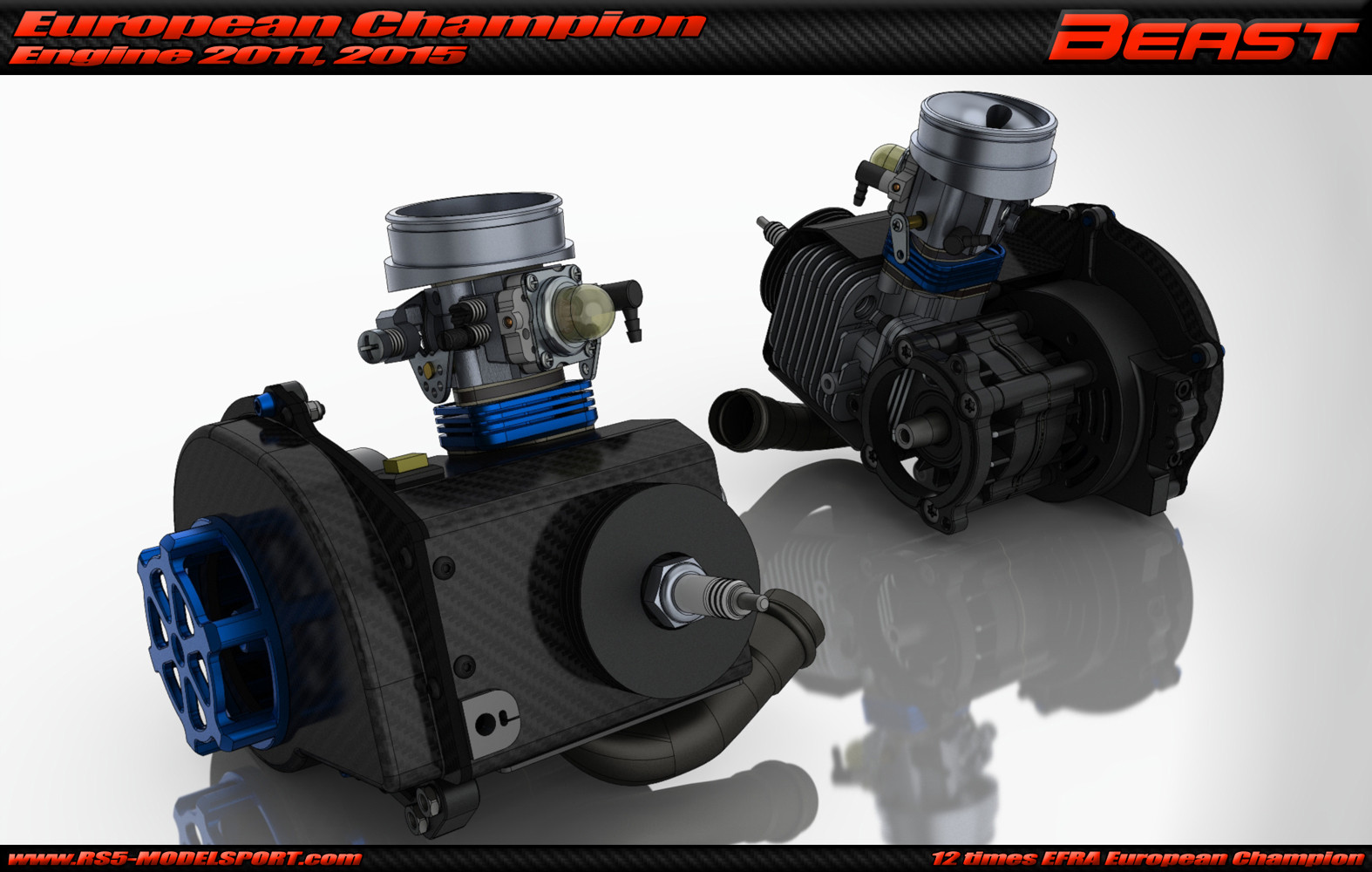

Carbon Engine Cover

The ventilator cover of the Beast engine made of 3mm thick Carbon, to optimise airflow and to reduce engine temperature. This carbon cover a way more resistant than the cast alloy cover of Zenoah engines. It protects well against a ventilator explosion, just in case. The cylinder cover also made of 1.5mm carbon. Both covers are CNC machined and made of high quality carbon fibre.

Our piston is ultra-light, its weight is only 19.0 grams. It is b 20% (4,5 gram) lighter than the standard Zenoah piston (23,5 gram). The piston modification is made completely with CNC machine. The piston has four windows on the side to increase to amount of mixture which goes up to the combustion chamber and to cool down the piston.

The Insulator Set is 3D CNC machined, which perfectly match with the ports of the Zenoah cylinder. It has heatsinks to increase the heat dissipation and to cool down inspired air. The shape of its inside channel is very important, so they are optimized to let the air in the cylinder in the best possible direction.

The Beast engine can be started only with an external electro starter. All Tx chassis kit and Tx conversion kit include an E-Starter rod with one-way bearing. With a battery drill you can easily start the Beast. Using this E-Starter design the ventilator can easily get air, because no component of the pull starter stays in the way of the air suction.